Our DIY Rocket Oven!

- Apr 27, 2020

- 5 min read

Updated: Jul 24, 2020

As a Western gal who moved to India, I really missed having an oven to bake! Most Indian households cook all means on a gas stovetop or a chula (woodfired stove). I was craving for roasting vegetables, baking breads, and crisping up granola.

As many do, in thinking about a wood fired oven, we agreed on a COB OVEN style. Cob ovens are big mammoth earthen beasts that rely on hours of heavy wood stoking and build up thermal mass to bake your food. They are pretty incredible; reaching epically high temperatures for pizza baking and holding their heat for 12+ hours, allowing you to progressively bake breads, then cookies, then granola and finally using the heat to dry out your saved seeds or oven roast sliced tomatoes.

The downside to cob? LOTS OF WOOD. LOTS OF TIME. Great for once a month Saturday night pizza cook ups, but not for thrice weekly bread baking as we had planned.

More thinking later and we arrived at the ROCKET OVEN. This permaculture 'appropriate technology' is a hyper-efficient heating machine - using mere kindling/small sticks to cook whole meals. The technology, which spans rocket mass heaters; rocket stoves; rocket ovens; even rocket hottubs and water heaters, relies on a J-TUBE shape burning chamber and super insulated heat riser to burn at a 100% fuel efficiency rate. Meaning anything 'rocket' burns completely clean and SMOKELESS. Smoke is simply unburned fuel; this technology utilizes all the wood's potential by burning the wood and all of its smoke, releasing out it's chimney nothing but hot air.

COB OVEN vs ROCKET OVEN

Let's review some pros and cons of both styles -

Skip head to get straight into the building process.

Cob Oven PROS:

-Burns super super hot (great for pizza) and holds it heat for a long time; meaning lots of potential baking in one session!

-Lower maintenance while slow baking things - you can put in your bread/cake/roast etc and walk away from the oven while its baking.

-Everything tastes 'wood-fired'

Cob Oven CONS:

-Requires LOTS of nice big timber to get a good fire

-Takes 3+ hours of stoking the beast to get it up to a temperature

-Ends up being a whole day's task to run your oven

-Everything tastes 'wood-fired' (also a con! what if you want to bake a wedding cake in there?)

-Produces smoke. Smoke, at any level, is still a pollutant. Smoke also means unburned fuel potential.

Rocket Oven PROS:

-Bake a ton of food using just kindling, small twigs, sticks! In most places, you should be able to fuel your fire; take a walk around your area, neighborhood, parks and collect fallen sticks.

-takes 30 minutes to preheat as compared to hours in a cob oven

-You can bake anything! There is no 'wood-fired' feel to the food, making it versatile for baking too.

-SMOKELESS. This baby burns completely clean. It really must be seen to be believed! It's a beautiful thing.

Rocket Oven CONS:

-You have to BE THERE at the oven for the whole duration of the bake. Feeding small sticks means near constant feeding. The maximum break you can take while its running is 5/10 minutes.

-If you are in a place with lots of big timber for firewood, it means more time on the ax making big logs into smaller pieces.

WHAT'S IT MADE OF?

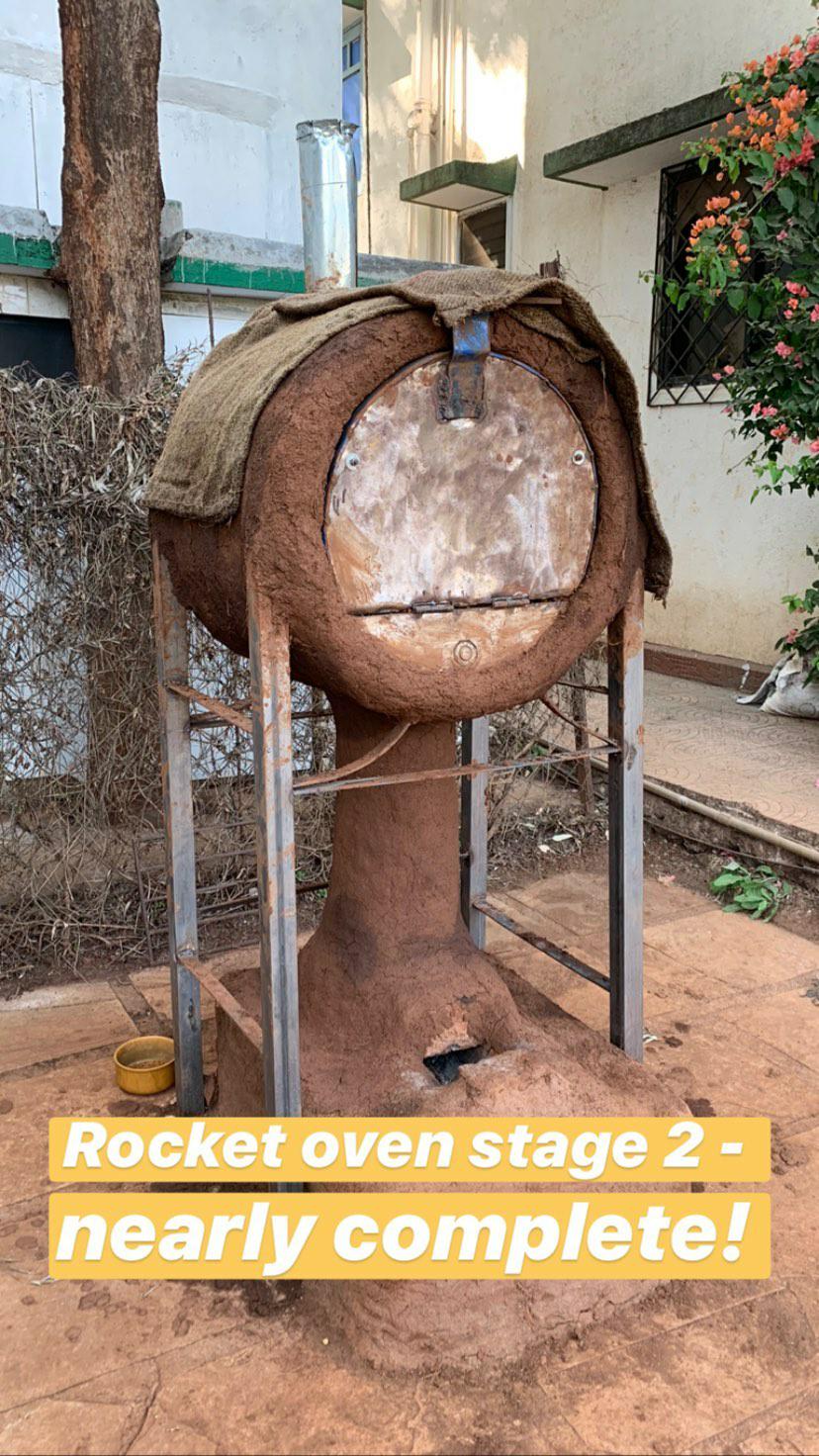

Here is the finished product.

Materials:

-bricks for base

-cob materials ie. sand, clay, and straw (in our case shredded coconut fiber)

-sawdust

-stainless steel sheeting to construct the heat riser and the chimney

-2x 200L metal shipping drums. If you can get barely used ones that is best! The one's we got were all banged up in a rubbish heap and we made em work.

-welding rod (we were lucky enough to have our cousin at the farm with some welding experience. You can also make this with nuts and bolts instead of welding)

-metal to make the stand

-hinges for oven door

-chicken wire

-more cob! lots and lots of cob. (cob = sand, clay & straw)

We bought our plans for $10 AUD from the legends over at Very Edible Gardens in Melbourne, Australia. They run frequent workshops building rocket ovens and really are pros at it. I would not have attempted this without some solid planning.

It takes a little while to get your head around it all; and our small team read that e-book cover to cover a couple times through this process. But don't sweat it; you'll get it. Buy Tim Barker's ebook The Rocket Powered Oven here.

OUR PROCESS

Our cousin Rohan was visiting us, he has some handy welding experience. We opted to weld our barrels together rather than use nuts and bolts & pop rivets and rivets, which we don't have quality access to here in Panchgani.

The other diversion we made from Barker's plan was to insulate the whole outside of the oven using only cob (in different styles and layers). His plans use fiberglass insulations batts and a outside cover of corrugated iron. The insulation batts are super common at Home Depots and Bunnings, but we couldn't find them anywhere in area. This option would have been easier, but I'm quiet happy with our cob work.

Otherwise we followed the plans to the T.

Essentially what you are doing is making a j-tube rocket stove base and attaching this upcycled barrel oven on top.

The hot air goes up insulated heat riser of the rocket stove portion into an opening in the bottom of the barrel oven. It circles around in the hollow portion between the two barrels (one outer, one inner with a couple inch gab all the way around). The hot air eventually escapes out a pipe in the back.

Making the J tube and heat riser is simple and straightforward.

The base is made with bricks and cob and sawdust. Easy and fun to do. The heat riser is two cylinders of stainless steel. In both, tabs are cut at the top and bottom to secure the smaller one within the larger one and maintain gap between. This gap gets packed with cob on either end and compact sawdust in the middle. The sawdust burns away to create a air vacuum for insulation. Later the whole heat riser got covered in chicken wire and more cob.

By far the trickiest part was cutting open the barrels with an angle grinder and tin snips, cutting the 'tabs' and welding them back to together. You have to cut the top and bottom off both barrels and do some crazy mad max work to get them back together. The outer barrel also gets a slit all down its belly to open it up so it can be wrapped around the inner barrel - creating a hollow 2 inch gap between the two barrels - this is for the hot air to circulate. Our barrels were in pretty rough shape, so its likely this process would have been easier with fresher barrels.

To see the whole progression, including short videos, head to our instagram page in the 'rocket oven' highlights section.

THE RESULT

We've now been burning this baby for 4 months or so and have cooked already dozens and dozens of amazing cakes, brownies, pizzas, sourdough breads, oven roasted veggies, strawberry pie, granola etc. etc. etc.

This was a fun challenge to build and we feel accomplished for it. I wouldn't have wanted to attempt this without The Rocket Oven e-book I mentioned earlier.

Hope you enjoyed and we hope you go build one yourself. It runs so efficiently, effectively and cleanly. This really is appropriate technology at its best

Big love to you all!

Namaskar,

I am delighted to receive the first news letter.. I haven't still finished reading all the stuff... but just couldn't stop responding on reading 'DIY Rocket Oven'... absolutely wonderful..!!

With my farm about 7 acres in a very small village in Latur district mostly rain fed and quite some pesticides and even chemical fertilizers being used for long, I have planned to go in for total organic methods of farming.. and I have already started working on.. would love to learn and practice sustainable agriculture and a sustainable life style.. and that's the reason why I attended NPC 2020.

I hope there is a lot in this regard to learn from what you are doing and practicing.

Thank you…